About This Service

Specialist shot blasting for factory and industrial cladding panels. We remove original plastisol, multiple layers of paint, rust, and weathering from metal cladding to restore surfaces to bare metal condition. Our precision techniques preserve the integrity of cladding panels while creating flawless surfaces ready for new protective coatings, extending the life of your building envelope.

Project Gallery: Industrial Warehouse Cladding Restoration

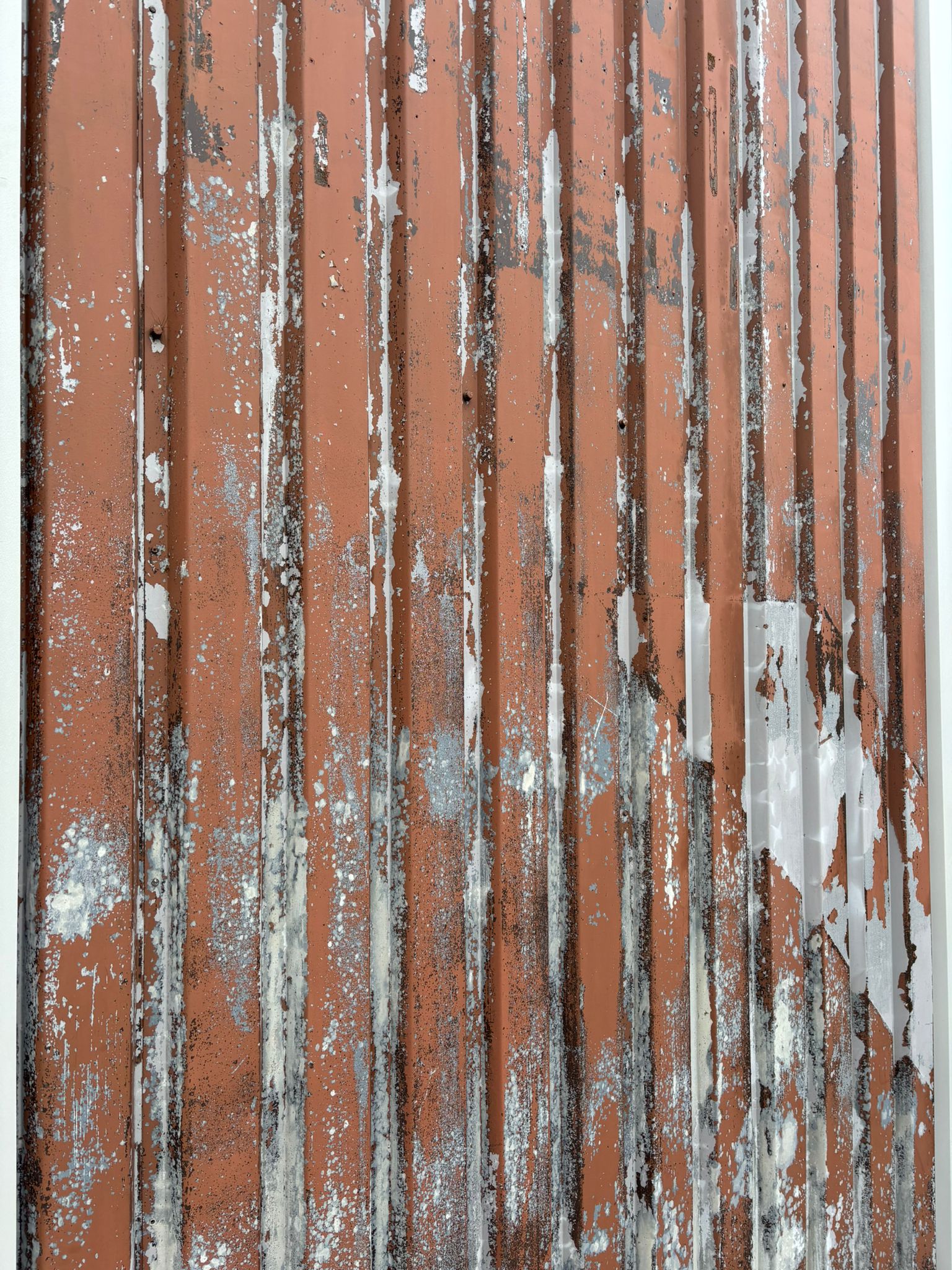

This project showcases the complete transformation of severely deteriorated warehouse cladding. The before images reveal the extent of the challenge: rust-coloured panels with original plastisol coating, multiple layers of failed paint, extensive peeling, and decades of weathering across the entire building envelope.

Before: Deteriorated Condition

Warehouse exterior with severely deteriorated cladding panels

Multiple paint layers and plastisol coating failure

Close-up showing extent of coating deterioration

Peeling paint, rust, and surface contamination

After: Complete Restoration

Transformation Complete

Clean, uniform bare metal surfaces ready for protective coating. All plastisol, paint layers, rust, and contaminants completely removed while preserving panel integrity.

Key Benefits

Our Process

Site Assessment

We assess cladding condition, coating types, and access requirements to plan the most effective blasting approach.

Area Protection

Work zones are contained and protected to control blast media and prevent contamination of surrounding areas.

Controlled Blasting

Using appropriate pressure and media, we systematically remove all coatings while preserving the cladding substrate.

Surface Inspection

Cleaned panels are inspected to ensure complete coating removal and proper surface profile for recoating.

Coating Coordination

Surfaces are prepared for immediate recoating to prevent oxidation and ensure optimal coating performance.

Applications

Case Studies

Industrial Warehouse Cladding Restoration

Manufacturing Facility Owner

Frequently Asked Questions

Yes, we can blast cladding panels while installed on buildings using specialized containment and access equipment, minimizing disruption to your operations.

No. Our experienced technicians use controlled pressure and appropriate blast media to remove coatings without damaging the underlying metal panels.

We coordinate closely with coating contractors to apply new coatings within 24-48 hours of blasting to prevent surface oxidation and ensure optimal adhesion.

Why Choose Us

Fully Insured

Comprehensive liability coverage

Experienced Team

Skilled professionals

On-Time Delivery

Projects completed to schedule

Other Services

Cookie Notice

We use cookies to enhance your browsing experience, analyse site traffic, and personalise content. By clicking "Accept All", you consent to our use of cookies. You can manage your preferences or decline non-essential cookies. Learn more